The true value of triple glazing isn’t just the extra pane; it’s determined by overlooked details in its specification and installation that dictate actual performance.

- Thermal comfort comes from a low U-value creating warm surfaces (radiant comfort), not just warmer air.

- Sealant quality and installation integrity are more critical for long-term performance than the choice between Argon or Krypton gas.

- A “full-frame” replacement with proper weather-resistant barrier (WRB) integration is non-negotiable for realizing the window’s full potential.

Recommendation: Focus on the entire window system—from glass coatings to the installer’s technique—to ensure your investment pays off in tangible comfort and quiet.

For any homeowner living on a noisy street or in a region with biting winters, the promise of a quieter, warmer home is deeply appealing. The conversation inevitably turns to windows, and the market presents a seemingly straightforward upgrade: triple glazing. The common advice suggests that three panes are simply better than two. It’s an easy-to-grasp concept, often positioned as the ultimate solution for energy efficiency and soundproofing. But this narrative oversimplifies a complex and expensive decision.

The debate shouldn’t be a simple tally of glass panes. The genuine performance delta between high-quality double glazing and premium triple glazing is often lost not in the product itself, but in a series of critical, often invisible, technical details. But what if the key to unlocking true value wasn’t just buying a more expensive window, but understanding the complete system? The real difference lies in the physics of thermal comfort, the longevity of the gas seal, the precision of the installation, and the specific acoustic properties of the glass assembly.

This guide moves beyond the sales pitch. We will deconstruct the components that deliver genuine heat and sound benefits. We will explore the science of thermal comfort, the realities of gas leakage, the critical importance of a flawless installation, and how to read acoustic ratings like an expert. By the end, you will be equipped to evaluate a window not by its pane count, but by its total system integrity, ensuring your significant investment translates into a truly comfortable and peaceful living space.

To navigate this technical landscape effectively, this article breaks down the crucial factors that determine whether the extra cost of triple glazing is a worthwhile investment for you. The following sections provide a clear roadmap to understanding each critical component.

Summary: Triple Glazing vs Double: Is the Extra Cost Worth the Sound and Heat Benefits?

- Why a Window with a Low U-Value Keeps Your Feet Warm in Winter?

- Argon vs Krypton: Which Gas Leaks Out of Windows Faster?

- The “Rip and Replace” Mistake That Destroys Your Water Barrier

- How to Read STC Ratings to Ensure You Block Traffic Noise?

- Which Direction Should Your Low-E Coating Face to Heat Your Home for Free?

- How to Set Your Bedroom Temperature to Maximize Slow Wave Sleep?

- Solar Integration vs Smart Meters: Which Reduces Tenant Utility Costs More?

- Exterior Thermal Insulation: ROI for Older Homes With Solid Walls?

Why a Window with a Low U-Value Keeps Your Feet Warm in Winter?

The primary benefit of triple glazing is its superior thermal performance, quantified by its U-value. A lower U-value means less heat is transferred through the window. However, the resulting comfort is more profound than just reducing your heating bill. It’s about changing the way you physically experience the space near your windows. This is due to a concept known as radiant comfort. Your body doesn’t just lose heat to the air (convection); it also radiates heat to colder surfaces around it. An old, single-pane window on a winter day might have a surface temperature near freezing, actively pulling warmth from your body and making you feel cold even if the thermostat is set to 21°C (70°F).

High-performance triple-glazed windows, which often achieve a U-factor of 0.30 or less as recommended for cold climates, maintain a much higher interior surface temperature. This significantly reduces radiant heat loss from your body. The engineering firm SimScale explains the underlying principle perfectly:

Mean radiant temperature (MRT) is a measure of the average temperature of all surfaces surrounding a person, including walls, floors, and objects. Unlike air temperature, MRT considers the radiant heat exchange between the human body and its surroundings.

– SimScale Engineering, SimScale CFD Analysis Documentation

By keeping the window pane’s surface temperature closer to the room’s air temperature, a low U-value window elevates the MRT of the entire room. This is why you can sit comfortably next to a triple-glazed window in winter without feeling a chill. A thermal imaging case study visually demonstrated this, showing a home with standard double glazing had significant energy loss through the panes, while a neighboring home with triple glazing showed almost no heat loss from the center of the glass. The result is not just a warmer room, but a fundamentally more comfortable one, from your head to your feet.

Argon vs Krypton: Which Gas Leaks Out of Windows Faster?

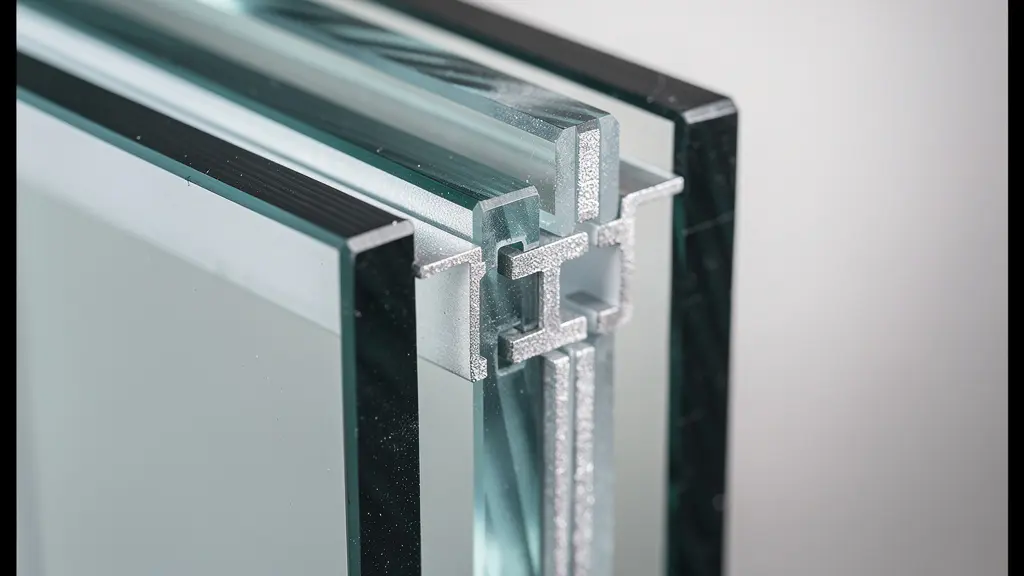

To lower the U-value, the space between the panes in an Insulated Glass Unit (IGU) is filled with an inert, non-toxic gas, most commonly Argon or Krypton. Because these gases are denser than air, they slow the convection of heat across the window, improving insulation. Krypton is a better insulator (and more expensive) than Argon, allowing for thinner gaps, but the performance of either gas is entirely dependent on one critical factor: the quality of the seal. If the gas leaks out, the window’s performance degrades significantly, eventually becoming little more than an expensive air-filled unit.

The unfortunate reality is that all seals will eventually fail and all gas-filled windows will leak. The key is the rate of leakage. A high-quality IGU is designed to minimize this loss. While there is no such thing as a “leak-proof” window, the industry standard for quality windows shows a gas leakage rate of about 1% per year. A poorly manufactured unit can lose its gas in just a few years, completely negating the initial investment. Therefore, the debate between Argon and Krypton is secondary to the quality of the IGU’s construction.

The longevity of your window’s thermal performance hinges on the sealants and spacers used to bond the panes together. Homeowners should focus their attention on the manufacturer’s quality control and certifications rather than the specific gas being used.

Action Plan: Verifying IGU Seal Integrity

- Sealant Quality: Ask the manufacturer about the quantity and quality of sealant used around the entire perimeter of the glass. It should be a dual-seal system.

- Corner Construction: Ensure the manufacturer uses continuous sealants with no gaps, especially at the corners, which are the most common failure points.

- Spacer Technology: Opt for “warm-edge” spacers instead of traditional aluminum. They reduce thermal bridging at the edge of the glass and put less stress on the seals during thermal expansion and contraction.

- Sealant Adhesion: Inquire about the manufacturer’s process for ensuring good adhesion of the sealants to both the glass and the spacer material.

- Certification: Choose IGUs that are certified to industry standards like ASTM E2188/E2190, which specifically test for long-term gas retention.

The “Rip and Replace” Mistake That Destroys Your Water Barrier

Even the most advanced triple-glazed window is only as good as its installation. A common shortcut that leads to catastrophic failure is the “insert replacement,” where a new window is simply placed into the frame of the old one. This method is faster and cheaper, but it completely fails to address the most critical element of window performance: water management. The real work of an installation happens at the rough opening, where the window unit must be perfectly integrated with the building’s Weather-Resistant Barrier (WRB), also known as the house wrap or building paper.

A proper “full-frame” (or “rip and replace”) installation involves removing the old window, frame, and trim down to the studs. This allows the installer to inspect for hidden rot, properly flash the opening using a shingle-lapped principle to direct water out and away, and create a continuous air and water seal between the new window and the WRB. This system integrity is what protects your home’s structure from moisture damage, mold, and rot. An insert replacement leaves the old, and potentially compromised, water management system in place, and often relies on a bead of caulk as the primary defense against water intrusion—a defense that is guaranteed to fail over time.

The choice between an insert and a full-frame replacement is a crucial decision point with significant long-term consequences for your home’s durability and the window’s actual performance. While the upfront cost of a full-frame replacement is higher, it is the only method that guarantees the window system will perform as designed.

This table outlines the critical differences, making it clear that the lower initial cost of an insert replacement comes with significant risks that a full-frame replacement eliminates.

| Aspect | Insert Replacement | Full-Frame Replacement |

|---|---|---|

| Cost | Lower initial cost | Higher upfront investment |

| Installation Time | Faster (1-2 hours per window) | Slower (3-4 hours per window) |

| WRB Integration | Limited – relies on existing frame | Complete – full weather barrier integration |

| Air Sealing | Partial – cannot address frame leaks | Complete – seals entire rough opening |

| Hidden Damage Detection | Cannot detect rot behind frame | Exposes and allows repair of damaged framing |

How to Read STC Ratings to Ensure You Block Traffic Noise?

For homeowners on busy streets, noise reduction is often a bigger driver than thermal performance. Triple glazing is marketed as a superior soundproofing solution, and while it can be, the details matter immensely. Many vendors will cite a window’s Sound Transmission Class (STC) rating. However, STC is a poor measure for the low-frequency rumble of traffic, trucks, and airplanes. It primarily measures mid-to-high frequency sounds like voices. For transportation noise, the Outdoor-Indoor Transmission Class (OITC) rating is a far more relevant metric.

A higher OITC number indicates better performance at blocking low-frequency noise. While high-performance modern triple-glazed windows with acoustic glass can achieve over 50 dB noise reduction, this is not achieved by simply adding a third pane of glass. The most effective soundproofing comes from a principle called acoustic asymmetry. This involves using panes of different thicknesses (e.g., 6mm, 4mm, and 8mm) within the same IGU. Each thickness is effective at blocking a different sound frequency, so combining them disrupts a much wider range of sound waves. Furthermore, using a laminated glass layer—two panes bonded together with a plastic interlayer—is exceptionally effective at dampening sound vibrations.

When evaluating windows for noise, ignore generic claims of “quiet” and demand specific OITC ratings and the exact glass configuration. A standard triple-glazed window with three identical panes might offer little acoustic improvement over a good double-glazed unit. The real performance comes from a system engineered specifically for sound abatement.

This guide helps connect common noise sources with the window specifications required to effectively block them, highlighting the importance of OITC over STC.

| Noise Source | Distance | Recommended Rating | Glass Configuration |

|---|---|---|---|

| Busy Highway | 100 yards | OITC 35+ | Triple glazing with asymmetric panes (6mm/4mm/6mm) |

| Airport Flight Path | 1 mile | OITC 38+ | Triple glazing with laminated layer |

| Neighborhood Playground | 50 yards | STC 32+ | Quality double glazing sufficient |

| Urban Traffic | Street-facing | OITC 34+ | Triple glazing or double with laminated glass |

Which Direction Should Your Low-E Coating Face to Heat Your Home for Free?

Modern windows are not just passive barriers; they are dynamic thermal systems, thanks in large part to Low-Emissivity (Low-E) coatings. These are microscopically thin, transparent metallic layers applied to one or more glass surfaces within the IGU. Their job is to reflect heat, but the direction they reflect it is critical. The placement of the Low-E coating determines whether the window is optimized to block solar heat or to capture it, and the correct strategy depends entirely on your climate and the window’s orientation.

To understand placement, you must know how window surfaces are numbered: Surface #1 is the exterior face of the outermost pane, Surface #2 is the interior face of that same pane, and so on. In a triple-glazed unit, there are six surfaces. In a cold climate, the goal is to allow free solar heat in during the winter but prevent your home’s internal heat from escaping. This is best achieved by placing the Low-E coating on Surface #4 or #6. This position allows short-wave solar radiation to pass through into the room, while reflecting the long-wave heat from your furnace and appliances back inside.

Conversely, in a hot climate, the priority is to block the sun’s heat from entering the home. This is done by placing the Low-E coating on Surface #2. This reflects solar heat before it can even penetrate the IGU. The window’s Solar Heat Gain Coefficient (SHGC) measures how much solar radiation it admits. A high SHGC is desirable for south-facing windows in cold climates, while a low SHGC is crucial for west-facing windows in hot climates. The correct Low-E coating and placement are essential for tuning your windows to your environment.

- Cold Climates: Place Low-E on surface 4 or 6 (counting from outside) to maximize passive solar heat gain in winter.

- Hot Climates: Place Low-E on surface 2 to block unwanted solar heat and reduce cooling costs.

- Mixed Climates: Use a spectrally selective Low-E coating on surface 2 or 3 for a balanced performance that blocks heat in summer but allows some solar gain in winter.

- South-Facing Windows (in cold/mixed climates): Choose a higher SHGC (above 0.40) to capitalize on free winter solar heat.

- West-Facing Windows (in hot/mixed climates): Select a very low SHGC (below 0.25) to block the intense afternoon sun.

How to Set Your Bedroom Temperature to Maximize Slow Wave Sleep?

The benefits of a high-performance building envelope extend beyond energy bills and into the realm of health and well-being, particularly sleep quality. Achieving deep, restorative slow-wave sleep is heavily influenced by your thermal environment. While most people focus on the air temperature set by the thermostat, the stability of the radiant temperature environment is just as important. A bedroom with poorly insulated windows will have cold surfaces that create uncomfortable micro-drafts and radiant heat loss, causing your body to work harder to maintain its core temperature, which can disrupt sleep cycles.

Triple-glazed windows contribute to a more stable and uniform thermal environment. By keeping the interior glass surface temperature close to the room’s air temperature, they eliminate cold spots and radiant heat sinks. A study on thermal comfort highlighted how even in a room with a stable average air temperature, a person standing near a radiator (a hot surface) would feel much warmer than someone near a cold window. Triple glazing minimizes these thermal sensations, creating a homogenous comfort zone that is conducive to sleep. The recommended bedroom air temperature for optimal sleep is cool, typically around 18°C (65°F), but this is only effective if the surrounding surfaces aren’t creating radiant heat imbalances.

A significant secondary benefit is the reduction of interior condensation. As DAKO Windows Research notes, “Triple glazed windows are less prone to interior condensation due to their higher surface temperature.” This not only improves indoor air quality by reducing the potential for mold growth but also protects the window frames and surrounding wall assembly from moisture damage, preserving the integrity of the entire building envelope over the long term.

Solar Integration vs Smart Meters: Which Reduces Tenant Utility Costs More?

When considering the financial return of triple glazing, the direct impact on utility bills is the most tangible metric. While smart meters can help manage energy consumption and solar panels can generate it, upgrading the building envelope with high-performance windows reduces the fundamental energy demand of the building. This “fabric-first” approach provides a permanent reduction in the energy needed for heating and cooling, delivering savings year after year.

The question is whether the incremental savings of triple glazing over high-quality double glazing justify the significant upfront cost. The answer depends on the baseline. Upgrading from old, leaky single-pane or early-generation double-pane windows to A++ rated triple glazing will result in dramatic savings. For example, UK-based research shows that upgrading from single glazing can yield annual savings of around £235 with A++ triple glazing versus £195 with A-rated double glazing. The delta between the two high-performance options is £40 per year in this scenario. For a business or homeowner, calculating the payback period is essential.

The return on investment (ROI) is not just about the energy delta. It’s a calculation that must include the increased property value, enhanced comfort, and improved acoustic environment. As one analysis on commercial upgrades notes, the energy savings from a double-to-triple-glazing upgrade can offset the initial investment in just a few years for many companies, especially those with large glazed areas. For a homeowner in a harsh climate or a very noisy location, the non-financial benefits of comfort and quiet might provide a much faster “personal ROI” than the utility bill savings alone would suggest.

Key Takeaways

- The true measure of a window’s thermal performance is its low U-value, which creates radiant comfort by keeping the interior glass surface warm.

- A full-frame replacement with proper integration into the home’s weather-resistant barrier (WRB) is non-negotiable to prevent leaks and realize the window’s performance potential.

- For blocking traffic noise, the OITC rating and the use of asymmetric or laminated glass are far more important than the standard STC rating.

Exterior Thermal Insulation: ROI for Older Homes With Solid Walls?

For owners of older homes, especially those with solid walls, improving the building envelope is the most effective path to lower energy bills and greater comfort. Applying exterior thermal insulation is a powerful upgrade, but its effectiveness can be severely compromised by a single weak link: old, inefficient windows. The building operates as a holistic system, and its overall performance is dictated by its worst-performing component.

After investing in wall insulation, the windows often become the primary source of heat loss. In a well-insulated building, studies indicate that up to 30% of total heat loss can occur through old windows. This is why a “fabric-first” approach must be comprehensive. Ignoring the windows after insulating the walls is like patching a bucket but leaving a large hole in the bottom. You will see some improvement, but you will never achieve the full potential for energy savings and comfort that the insulation promises.

The Passive House Institute, a leader in building science, encapsulates this principle perfectly. Their fundamental philosophy is that “The overall thermal performance of the building is always dragged down by its worst-performing component.” Therefore, the decision to upgrade to triple glazing should not be seen in isolation. It is an integral part of a complete strategy to create a high-performance building envelope. For an older home with newly insulated walls, high-performance windows are not a luxury; they are the necessary next step to complete the thermal barrier and maximize the return on the entire insulation investment.

Ultimately, investing in triple glazing is an investment in system integrity. By focusing on the critical details—a low U-value for radiant warmth, robust seals for longevity, a full-frame installation for water management, and the right acoustic specifications for quiet—you ensure the extra cost translates directly into a higher standard of living. To apply these principles, the next logical step is to engage with certified installers who understand and can execute these technical requirements flawlessly.