A strategic facade renovation is an investment in your home’s high-performance building envelope, not just a cosmetic update, delivering significant ROI through enhanced value and efficiency.

- Modern cladding systems, like rainscreens, actively manage moisture to prevent costly rot and mold damage within your walls.

- Advanced materials such as fiber cement offer superior resistance to fire, rot, and fading compared to traditional options, reducing long-term maintenance.

Recommendation: Shift your focus from simply choosing a siding color to designing an integrated exterior system that boosts your home’s resilience, safety, and appraised value.

For homeowners looking to modernize their property, the facade is often the first consideration. The common approach focuses on “curb appeal”—a fresh coat of paint or new siding to enhance the look. While aesthetics are important, this view often misses the most critical function of your home’s exterior: its performance as a complete system. Thinking only about the surface material is like choosing a car based solely on its color while ignoring the engine, safety features, and fuel economy.

True modernization goes deeper than skin-deep. It involves upgrading the entire building envelope, the barrier that separates your indoor environment from the elements. This is where the real value—both in terms of financial return and living comfort—is generated. The conversation needs to shift from “what color?” to “what system?” This involves understanding how materials interact, how they manage moisture, and how they contribute to your home’s thermal performance.

The secret to a successful and profitable facade renovation lies in a strategic, systems-based approach. By prioritizing technical performance over simple cosmetics, you’re not just giving your house a facelift; you’re engineering a more resilient, efficient, and valuable asset. This guide will explore the key architectural and material science principles that turn a standard cladding project into a powerful investment. We will deconstruct the systems, compare the materials, and analyze the financial returns that prove a well-designed facade is one of the smartest upgrades a homeowner can make.

This comprehensive article breaks down exactly how to approach your facade renovation as a strategic investment. Below is a summary of the key topics we will cover to guide you through the process.

Summary: A Strategic Guide to Facade Modernization

- Why Modern Cladding Can Increase Appraised Value by 10%?

- How a Rain Screen Cladding System Prevents Mold in Your Walls?

- Cedar vs Fiber Cement: Which Cladding Resists Rot and Fading Better?

- The Flammable Cladding Mistake That Is Illegal in Many Jurisdictions

- How to Navigate HOA Rules When Changing Your Facade Color?

- How to Retrofit Older Apartments with Smart Tech for Under $500 per Unit?

- How a 20% Down Payment Magnifies Your Cash-on-Cash Return?

- Exterior Thermal Insulation: ROI for Older Homes With Solid Walls?

Why Modern Cladding Can Increase Appraised Value by 10%?

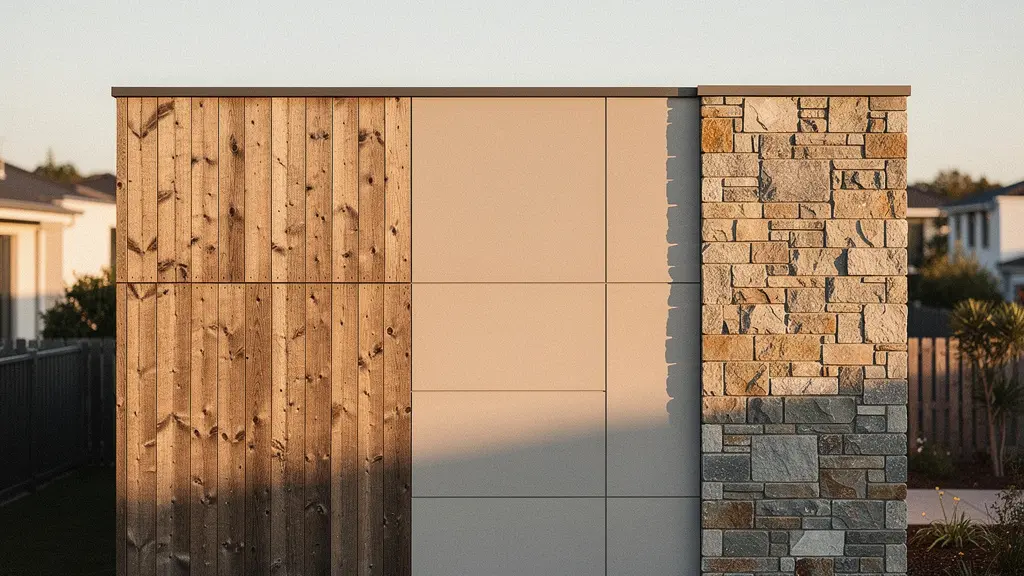

A facade renovation directly increases a home’s appraised value by impacting two key factors: enhanced curb appeal and the perception of reduced future maintenance. While a 10% increase is a strong benchmark, certain high-performance materials can yield even more impressive returns. For instance, recent data shows manufactured stone veneer delivers an astonishing 208% return on investment. This isn’t just about looking good; it’s about signaling quality and durability to potential buyers and appraisers.

Consider a practical example: replacing a section of dated vinyl siding with manufactured stone veneer. A project with an average cost of $11,287 can add an estimated $17,291 to the home’s resale value. This financial gain stems from the material’s high-end aesthetic, its promise of longevity, and its low-maintenance profile. Appraisers recognize that a home with a robust, modern exterior will cost less to maintain over time, justifying a higher valuation. The investment signals that the home has been well-cared-for and is protected by a resilient building envelope.

Therefore, the value increase is not just a guess; it’s a calculated outcome based on market data. Choosing a cladding material is an investment decision. By selecting materials known for their durability and high ROI, you are actively increasing your property’s equity. It transforms an expense into a capital improvement that pays for itself—and then some—at the time of sale or appraisal.

How a Rain Screen Cladding System Prevents Mold in Your Walls?

The single greatest threat to a wall’s structural integrity is trapped moisture. When water penetrates the exterior siding and has no way to escape, it leads to rot, mold, and catastrophic damage to the underlying structure. Traditional cladding applied directly to the sheathing can trap this moisture. A rainscreen system is an advanced architectural solution designed specifically to prevent this problem.

It’s not just a type of cladding, but an assembly method. As leading building resources explain, it involves creating a dedicated air gap between the back of the siding and the home’s water-resistive barrier.

A rainscreen is an exterior wall detail where the siding (wall cladding) stands off from the moisture-resistant surface of an air/water barrier applied to the sheathing to create a capillary break and to allow drainage and evaporation.

– Wikipedia Contributors, Rainscreen Systems Technical Definition

This gap, typically between 3/8″ and 3/4″, is the critical component. It provides a clear drainage path for any water that gets behind the cladding, allowing it to harmlessly exit at the bottom of the wall. Furthermore, it promotes constant air circulation, which actively dries out the wall assembly. This ventilation is key to preventing the damp, stagnant conditions that mold and rot thrive in. The image below illustrates this multi-layered defense.

As the cross-section shows, a rainscreen is a complete moisture management system. By creating a pressure-equalized air cavity, it neutralizes the wind-driven forces that push water into wall cavities. Investing in a rainscreen system is investing in your home’s long-term health, protecting your structure from the inside out and ensuring the longevity of your entire building envelope.

Cedar vs Fiber Cement: Which Cladding Resists Rot and Fading Better?

When selecting a cladding material, durability is paramount. While natural wood like cedar offers timeless beauty, it comes with significant maintenance demands. Fiber cement, a composite of cement, sand, and cellulose fibers, has emerged as a superior alternative from a material science perspective, particularly in resisting rot and fading.

The primary difference lies in their reaction to moisture and UV exposure. Cedar is an organic material susceptible to rot if not meticulously maintained. It requires regular treatment with preservatives and staining to prevent deterioration. In contrast, fiber cement is an inert material. It does not absorb moisture, making it virtually immune to the rot and decay that plague wood. This translates directly to maintenance: maintenance data reveals that cedar often requires repainting or re-staining every 3-5 years to maintain its appearance and protective qualities, while high-quality fiber cement comes with a factory-applied finish that can last for 15 years or more before needing a refresh.

Fiber cement’s durability extends beyond rot resistance. It boasts exceptional dimensional stability, meaning it won’t warp or buckle when exposed to fluctuating temperatures and humidity. Its dense composition also provides superior resistance to hail and impacts. Furthermore, the baked-on color finishes are specifically engineered to resist fading from UV rays far longer than typical wood stains. With a potential lifespan of 40-50 years with minimal upkeep, fiber cement offers a “set it and forget it” peace of mind that cedar simply cannot match without constant and costly intervention.

The Flammable Cladding Mistake That Is Illegal in Many Jurisdictions

A facade renovation is also an opportunity to significantly upgrade your home’s safety, specifically its resistance to fire. The choice of cladding material is a critical decision that can either add fuel to a fire or act as a protective barrier. Using combustible or easily melted materials is a grave mistake, and in many areas, particularly for multi-story buildings, it is now illegal.

Materials like vinyl siding and untreated wood pose a significant fire risk. Vinyl can melt and warp when exposed to even moderate heat from a nearby barbecue grill, let alone a house fire, exposing the structure underneath. Untreated wood siding, especially as it ages and dries, can act as kindling. This is in stark contrast to non-combustible materials like fiber cement. As a material composed of sand and cement, it will not ignite under direct flame. In fact, fire testing standards confirm fiber cement has a flame spread rating of 0 and a smoke-developed index of 0, the same classification as brick or stone.

Following tragic high-rise fires around the world, building codes have become far more stringent about exterior cladding. Regulators are increasingly mandating non-combustible materials for building exteriors to prevent rapid fire spread up the facade. While a single-family home might not face the same regulations as a skyscraper, the principle remains the same: your cladding should contain a fire, not contribute to it. Choosing a Class A fire-rated material like fiber cement is not just a code-compliant decision; it’s a fundamental safety measure that protects your property and, more importantly, your family.

How to Navigate HOA Rules When Changing Your Facade Color?

While you may own your home, the exterior appearance is often subject to the rules of a Homeowners Association (HOA). Before embarking on any facade renovation, navigating the HOA’s architectural guidelines is a critical first step. An unapproved project can result in fines and legal orders to undo the work, turning an exciting upgrade into a costly nightmare.

The key to a smooth process is proactive and thorough communication. Don’t assume your color or material choice will be accepted. Instead, treat it as a formal proposal that requires clear documentation and adherence to a specific process. The goal is to make it as easy as possible for the architectural review committee (ARC) to say “yes.” Some jurisdictions have laws governing response times; for example, one legal overview notes that in California, the Davis-Stirling Act gives an HOA 45 days to respond before a request is deemed approved. This highlights the formal nature of the process.

To ensure success, a systematic approach is best. Following a clear plan of action can prevent misunderstandings and expedite approval, allowing your project to proceed without delay.

Action Plan: Your HOA Approval Checklist

- Review Documents: Thoroughly read the association’s CC&Rs (Covenants, Conditions & Restrictions) and architectural guidelines to understand the exact procedures, approved color palettes, and material restrictions.

- Create a Detailed Proposal: Assemble a complete package including drawings, material samples (e.g., a piece of the fiber cement siding), paint color chips, and photos of your home and perhaps neighboring homes to show context.

- Submit a Formal Application: Use the official HOA application form. Fill it out completely and attach all required documentation, paying close attention to submission deadlines.

- Engage Constructively: If the board has questions or concerns, schedule a meeting to discuss them. Be open to feedback and willing to explore acceptable alternatives if your first choice is denied.

- Confirm Final Approval in Writing: Do not order materials or start any work until you have received formal, written approval from the HOA or ARC.

How to Retrofit Older Apartments with Smart Tech for Under $500 per Unit?

When we think of “smart tech” for a home, we usually picture Wi-Fi thermostats and voice-activated lights. But from an architectural perspective, the “smartest” technology you can add to an older building isn’t a gadget—it’s a high-performance building envelope. A modern cladding system is a passive, intelligent layer that works 24/7 to manage temperature, moisture, and energy usage without any human input.

The principle behind targeted smart tech retrofits—achieving maximum impact with a focused investment—applies perfectly to facade upgrades. Rather than a piecemeal approach, a strategic investment in a new cladding system provides a holistic, building-wide upgrade. For an older apartment with poor insulation and drafty walls, a new exterior insulation and cladding system is far more impactful than an individual smart thermostat in every unit. The thermostat can only try to compensate for energy loss; the new envelope prevents that loss in the first place.

This “passive smart tech” delivers returns every single month through lower energy bills for tenants and reduced operational costs for the owner. It enhances comfort by eliminating cold spots and drafts, and it protects the building’s structure from long-term decay. While the upfront cost exceeds the “under $500 per unit” benchmark for small gadgets, the long-term ROI in energy savings, increased property value, and tenant retention makes it one of the most intelligent investments possible for an older building.

How a 20% Down Payment Magnifies Your Cash-on-Cash Return?

In real estate investing, a down payment isn’t just a cost; it’s leverage that magnifies returns. The same financial logic can be applied to a strategic facade renovation. The significant upfront cost of a high-quality cladding project should be viewed not as an expense, but as a “down payment” on your home’s future performance and equity. This initial investment directly magnifies your “return” in two distinct ways.

First, it generates a direct, monthly “cash” return in the form of energy savings. By upgrading to an insulated cladding system, you drastically reduce thermal bridging and improve your home’s R-value. This translates into lower heating and cooling bills every month. This consistent saving is a tangible return on your initial outlay, effectively putting money back in your pocket over the life of the home. It’s an annuity paid out by your home’s enhanced efficiency.

Second, the investment unlocks a substantial return in the form of magnified equity. As established, a quality facade upgrade significantly increases your home’s appraised value. This increase is often far greater than the project cost, as seen with the 208% ROI on stone veneer. When you sell or refinance, you capture this magnified value. By investing a lump sum upfront, you are leveraging that capital to generate a much larger gain in your home’s equity, perfectly mirroring how a down payment allows an investor to control a larger, appreciating asset.

Key Takeaways

- True value comes from designing a complete “building envelope system,” not just a cosmetic finish.

- Material science is key: Fiber cement offers superior durability and safety over traditional wood.

- A rainscreen system is a non-negotiable architectural detail for long-term moisture management and structural protection.

Exterior Thermal Insulation: ROI for Older Homes With Solid Walls?

Older homes, particularly those with solid masonry walls, are notoriously inefficient. They lack the cavity space for modern insulation, leading to significant heat loss, high energy bills, and uncomfortable indoor temperatures. For these properties, Exterior Thermal Insulation (ETI), often as part of a new cladding system, offers one of the highest returns on investment of any renovation project.

ETI involves affixing a layer of rigid insulation board to the exterior of the existing wall, which is then covered with a new cladding material. This approach effectively wraps the home in a continuous thermal blanket, eliminating thermal bridges—points where heat can easily escape through structural elements. This dramatically improves the wall’s overall R-value, or resistance to heat flow. The result is a home that stays warmer in the winter and cooler in the summer with significantly less energy consumption.

Case Study: Energy Code Compliance Through Retrofits

Retrofitting older buildings is a key driver in the construction market, allowing them to meet modern energy codes and remain competitive. A typical high-impact retrofit includes installing new exterior cladding systems with continuous insulation, high-performance double-glazed windows with thermally broken aluminum frames, and sometimes dynamic shading. By improving both the appearance and the thermal performance, these upgrades can help older buildings earn environmental certifications like LEED, drastically lower air-conditioning costs by reducing solar heat gain, and extend the building’s viable lifespan.

The return on investment for ETI is multi-faceted. The most immediate return is the drastic reduction in monthly utility bills, which can often be cut by 25-40% or more depending on the climate and the home’s original condition. Over the long term, this adds up to tens of thousands of dollars in savings. Furthermore, it significantly boosts the home’s comfort and marketability, contributing to a higher appraisal value. For owners of older homes with solid walls, ETI is not just an upgrade; it’s a fundamental transformation of the property’s performance and financial viability.

Ultimately, a successful facade renovation is a testament to systems thinking. By shifting your perspective from a simple cosmetic update to a comprehensive upgrade of your building envelope, you unlock transformative value. The next logical step is to consult with an architect or a certified exterior designer to analyze your specific property and design a system that delivers on aesthetics, performance, and financial return.

Frequently Asked Questions About Facade Cladding Renovation

What makes cladding fire-resistant?

The fire resistance of cladding is determined by its material composition. Materials like fiber cement, which are made of non-combustible components like sand and cement, are typically 1-hour fire-resistance rated. They will not ignite or contribute fuel when exposed to direct flame or heat and carry a flame spread rating of 0, achieving a Class A fire rating.

Why do some claddings fail fire safety codes?

Some cladding materials fail fire codes because they are inherently combustible or have a low melting point. For example, vinyl siding can easily melt when exposed to a significant heat source, exposing the wall structure beneath. Untreated cedar siding, being a natural wood product, can become fuel in a fire, contributing to its spread.

How do building codes address cladding fire safety?

Building codes are increasingly strict regarding cladding fire safety, especially on multi-story and commercial buildings. Following major fire incidents globally, many jurisdictions have banned high-risk, combustible cladding products. This has led to a surge in demand for non-combustible alternatives, with materials like metal panels and fiber cement gaining significant market share as regulators push for safer building exteriors.